Changzhou Fuyi Drying Equipment Co., Ltd.

Address: No. 212 Huaxing Road,Jintan Development Zone,Changzhou,Jiangsu,China

Tel: 0086-519-80181222

Fax: 0086-519-80181222

Mobile: 0086-18706143009

Skype:syhjtyz

E-mail: fy@fuyigz.com;

steven@fuyigranulation.com

Contact person: STEVEN

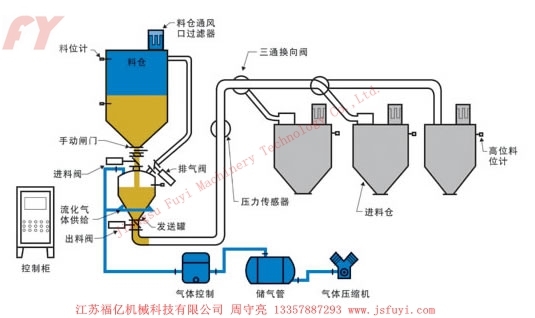

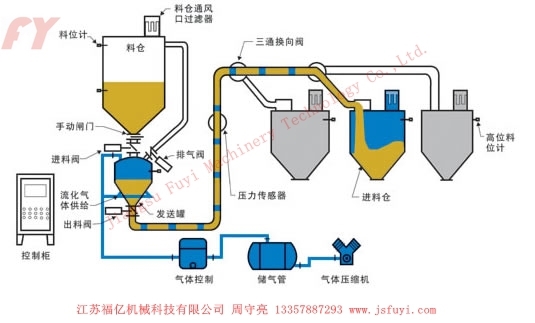

Delivery tank flow mode delivery

1.Principle

In the feed process, through the bell valve, double butterfly valve or expansion butterfly valve through the gravity of the material to the delivery tank, the replacement of air through the exhaust valve to make it easier to feed. Once the sending tank fill (or weighing display material to realize the 80% layer volume), the intake valve and the exhaust valve is automatically closed and sealed, and then sent by a high-pressure gas tank, the nozzle flow at the top of the gradually increased, the gas mixture within the tank and adding materials to automatically open the exhaust valve when the tank pressure reaches the set value, the flow state in pipeline the material in the pressurized tank and pipeline emptying until sending. When the pressure in the delivery tank drops to zero, the air supply valve closes, while the remaining gas is discharged from the delivery tank and the delivery line.

2. Applicable material:

This method is usually applied to shorter transmission lines, distances and very fine and non abrasive powder materials such as talc, flour, calcium carbonate, etc.. The fluid delivery tank uses a fluidizing nozzle to transport the material during the delivery. It eliminates the internal obstruction and improves the flow rate so that the powder material is transported as liquid.

3.Component:

The fluidization system mainly consists of a fluid delivery tank, an electric control system and a transmission pipeline.

4. Characteristic:

The system is characterized by high gas flow and low delivery pressure throughout the delivery process.

5. Process flow diagram