Changzhou Fuyi Drying Equipment Co., Ltd.

Address: No. 212 Huaxing Road,Jintan Development Zone,Changzhou,Jiangsu,China

Tel: 0086-519-80181222

Fax: 0086-519-80181222

Mobile: 0086-18706143009

Skype:syhjtyz

E-mail: fy@fuyigz.com;

steven@fuyigranulation.com

Contact person: STEVEN

Product introduction

Hollow blade dryer,Applicable for drying or cooling of paste, particle, powder and slurry state of material, perform the process of drying, cooling, heating, sterilizing, reacting and combustion under low temperature. The special stirring and heating transferring blade, makes high heat transferring efficiency, and provide self-cleaning function. The special chock shaped stirring and heat transferring blade has high heating efficiency and self-cleaning function of the heating transferring surface.

Working principle

Hollow chock shaped blades are concentrated on the hollow shaft. Heat media flow through the blade from the hollow shaft. The heat transferring area in the effective volume is very high. The temperature range of heating media is -40 ℃ to 320 ℃ . It might be steam, or liquid state, such as steam, thermal oil etc. Indirect heating, there's no heat carried out by air. All heat is utilized for to drying the material except the lost of heat insulation layers. The surface of chock shaped blade has self-cleaning function. The relative movements of the product particles and the chocked shaped surface might clean the material attached to the chock shaped surface, so to keep the cleanliness of heat transferring surface during working. The shell of hollow blade dryer is Ω shape. 2 or 4 pieces of hollow stirring shaft are usually equipped in the shell. To avoid any leakage of material, there're sealed terminal cover and top cover with the shell. The heat transferring media flow through the rotation connector, jacket's shell and hollow stirring shaft. To ensure best transferring effect, the hollow stirring shaft adopts different interior structure in accordance with different heating media.

Characteristics

|

The heat consumption of blade is low |

No heat carried out by the air because of indirect heating. there's no heat insulation layer with the exterior wall of the dryer. It consumes 1.2 kg of steam to evaporate 1kg of water for to drying slurry state of material |

|

The cost of the blade dryer is low |

The unit effective volume has very large heat transferring surface. Processing time is shorted, the size of the equipment becomes small.

The building area and place are sharply decreased. |

|

The range of material to be processed is wide |

Heat sensitive material and the materials to be processed under high temperature might be processed with different heating media. The normal media are: steam, thermal oil, hot water and chill water. It might be continuous or batch operation, widely used in many areas.

|

|

The pollution is less |

Without any carrying air, very few powder is carried out. The solvent evaporated is very few, it easy to be processed. For the material that might cause pollution or the solvent to be recovered, it might adopt sealed circulation. |

|

The operation cost is low |

1hour/day.operator is enough for normal operation. Low stirring speed and reasonable structure. The worn amount is few, and the maintenance fee is low. |

|

Steady operation |

The material particles fully contact heat transferring surface, because of the special compressing and swell-stirring effect of the chock shaped blade. The difference of the temperature, humidity and mi Material to be dried |

Blade dryer has been successfully used in food, chemical, petrochemical, dye, industrial sludge and other fields. Equipment heat, cooling, mixing features make it to complete the following unit operations: calcination (low temperature), cooling, drying (solvent recovery), heating (melting), response and sterilization. Mixing blades at the same time the heat transfer surface, the effective volume per unit area of heat transfer increases, reducing the processing time. Heat transfer surfaces in wedge-shaped blades with self-cleaning function. Compression - Expansion mixing features make the material mixed uniformly. Material along the axis into a "plug flow" movement, in the axial zone, the material temperature, humidity, mixing a very small degree of gradient.

1. Conducting oil to do with the heat medium, blade dryer to complete the work of low-temperature calcination. Such as: calcium sulfate dihydrate (Ca2SO4 · 2H2O) calcined into calcium sulfate hemihydrate (Ca2SO4 · 1/2H2O). Sodium bicarbonate (NaHCO3) into calcined soda (Na2CO3) and so on.

2. Pass into the cooling medium, such as water, salt, etc. can be used to cool the cooling. Such as: use of soda ash industry in blade-type cooler base machine to replace the old air-cooled cooler base machine, saving energy and exhaust gas processing equipment, lower operating costs, but also for titanium, nickel alloy powder and all kinds of powder granular materials cooling. On a single machine where the material can be cooled from 1000 °C to less than 40 °C.

3.Dry, the main function of equipment, do not use hot air to solvent recovery, energy consumption, environmental control is easy to deal with the ideal state. On the need to recover solvents, heat-sensitive materials, particularly flammable adapt easily oxidized. Has been widely used in fine chemical, petrochemical, dye industry.

4. Axial range, temperature, humidity, mixing degree of uniformity, so equipment can be used to heating or melting, or some solid material response. In the compound and modified starch industries have been successfully used. Blade dryer can be used to carry out sterilization of food and flour. Unit within the effective volume of a large heating area, will soon be material heated to sterilization temperature, to avoid prolonged heating change the quality of materials.

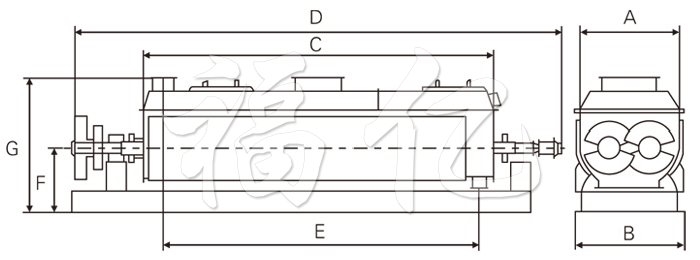

Sketch of installation structure

Technical specifications

|

Project/model |

JYG3 |

JYG9 |

JYG13 |

JYG18 |

JYG29 |

JYG41 |

JYG52 |

JYG68 |

JYG81 |

JYG95 |

JYG110 |

|

Heat transfer area(m2) |

3 |

9 |

13 |

18 |

29 |

41 |

52 |

68 |

81 |

95 |

110 |

|

Effective volume(m3) |

0.06 |

0.32 |

0.59 |

1.09 |

1.85 |

2.8 |

3.96 |

5.21 |

6.43 |

8.07 |

9.46 |

|

Speed range (rmp) |

15-30 |

10-25 |

10-25 |

10-20 |

10-20 |

10-20 |

10-20 |

10-20 |

5-15 |

5-15 |

5-10 |

|

Power(kw) |

2.2 |

4 |

5.5 |

7.5 |

11 |

15 |

30 |

45 |

55 |

75 |

95 |

|

Width of body A(mm) |

306 |

584 |

762 |

940 |

1118 |

1296 |

1476 |

1652 |

1828 |

2032 |

2210 |

|

Total widthB(mm) |

736 |

841 |

1066 |

1320 |

1474 |

1676 |

1854 |

2134 |

1186 |

2438 |

2668 |

|

Width of body C(mm) |

1956 |

2820 |

3048 |

3328 |

4114 |

4724 |

5258 |

5842 |

6020 |

6124 |

6122 |

|

Total length D(mm) |

2972 |

4876 |

5486 |

5918 |

6808 |

7570 |

8306 |

9296 |

9678 |

9704 |

9880 |

|

Feed distance E(mm) |

1752 |

2540 |

2768 |

3048 |

3810 |

4420 |

4954 |

5384 |

5562 |

5664 |

5664 |

|

Center height F(mm) |

380 |

380 |

534 |

610 |

762 |

915 |

1066 |

1220 |

1220 |

1220 |

1220 |

|

Total height H(mm) |

762 |

838 |

1092 |

1270 |

1524 |

1778 |

2032 |

2362 |

2464 |

2566 |

2668 |

|

Intake port N(inch) |

3/4 |

3/4 |

1 |

1 |

1 |

1 |

11/2 |

11/2 |

11/2 |

11/2 |

2 |

|

Outlet O(inch) |

3/4 |

3/4 |

1 |

1 |

1 |

1 |

11/2 |

11/2 |

11/2 |

11/2 |

2 |