Changzhou Fuyi Drying Equipment Co., Ltd.

Address: No. 212 Huaxing Road,Jintan Development Zone,Changzhou,Jiangsu,China

Tel: 0086-519-80181222

Fax: 0086-519-80181222

Mobile: 0086-18706143009

Skype:syhjtyz

E-mail: fy@fuyigz.com;

steven@fuyigranulation.com

Contact person: STEVEN

Summary

The XSG Rotary Flash Evaporation Dryer is new and high-efficiency fluidized drying equipment which is researched and developed for the sake of overcoming the low—efficiency and high- consumed static drying by our company. We have joined the characteristics of ordinary fluidized drying such as air stream drying, in designing process, and have developed advantaged and reduced shortcoming with the advantageous usage function. All this really helps the rotary drying equipment to realize the target of the consuming and high efficiency of the fluidized drying.

Working principle

Hot air enters into stirring and drying chamber from the bottom of dryer with suitable atomizing speed. It exerts strong shearing, blowing, floating and rotating effect to raw material. Therefore raw material is granulated through centrifugation, shearing, impacting and friction effect. It strengthens the process of heat exchange. At the bottom of rotary flash dryer, the large and damp granule is crushed under the action of stirrer and the granule that is small in particle and contain less moisture will lift accompanied with revolving air stream. During the period of lift, it is dried further. Because gas and solid two phases flow in heat exchange, so the evaporation dryer has strong drying capacity.

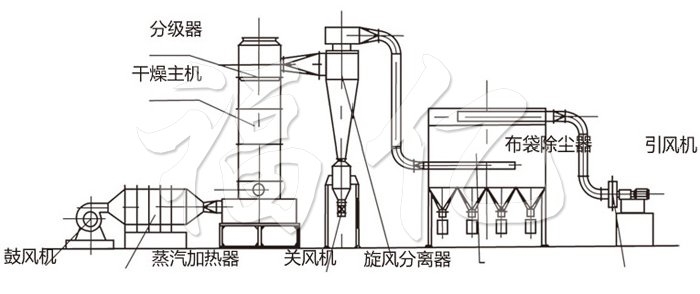

Process flow diagram

Flash diagrammatic sketch

Features of this rotary drying equipment:

1. Hot air enters into stirring and crushing and drying chamber from the bottom of drier with suitable atomizing speed. It exerts strong shearing, blowing, floating and rotating effect to raw material

2. Dry gas enters into the bottom of drier, generating strong rotating airflow, thus making a strong rushing effect for the material stuck on the wall to eliminate the phenomenon that the material stuck on the wall.

3. In the high temperature zone of the bottom of dryer, heat sensitive material does not close contact with hot surface, and special device was equipped at the bottom of dryer to solve the problem that the coking discoloration of heat-sensitive materials.

4. Due to the high speed of gas at circle inside the drying chamber and the staying time of raw material is short, high efficiency and quick speed can be realized

5. There are elutriation ring and rotating flow at the top of the drying chamber to control the size and temperature of the product. So it can meet the requirement moisture and granule of different raw material.

6. The circle speed in the drying chamber is high and the material staying time is short, so it effectively provides the materials from being sticking to wall and heat sensitive materials.

Application scope of the rotary flash dryer:

Organics: Atrazine (pesticides), lauric acid cadmium benzoic acid, sodium oxalate, sterilization Dan, cellulose acetate, organic pigments, etc

Dyestuff: Anthraquinones, black iron oxide, indigo dye, butyrate, titanium oxide, zinc sulfide, various azo dye intermediates

Inorganic substance: Borax, calcium carbonate, hydrogen peroxide, copper sulfate, ferric oxide, TanSuanBei, three antimony oxide, all kinds of metal salt, synthetic cryolite etc.

Foodstuff: Soybean protein, gelatinized starch, vinasse, triticum, wheat starch

|

Model |

Diameter of barrel(mm) |

Size of main machine(mm) |

Power of main machine(KW) |

Air processing volume(m3/h) |

|

XSG-2 |

200 |

250×800 |

0.75-2.2 |

300-800 |

|

XSG-3 |

300 |

400×300 |

3-4 |

600-1500 |

|

XSG-4 |

400 |

500×500 |

4-7.5 |

1250-2500 |

|

XSG-5 |

500 |

600×000 |

5.5-11 |

1500-4000 |

|

XSG-6 |

600 |

700×200 |

7.5-18.5 |

2500-5000 |

|

XSG-8 |

800 |

900×600 |

11-18.5 |

3000-8000 |

|

XSG-10 |

1000 |

1100×000 |

15-30 |

5000-12500 |

|

XSG-12 |

1200 |

1300×200 |

15-37 |

10000-20000 |

|

XSG-14 |

1400 |

1500×400 |

30-55 |

14000-27000 |

|

XSG-16 |

1600 |

1700×1000 |

45-75 |

18700-36000 |

Dried Sample

|

|

|

Name of raw materials |

Initial water content (%) |

Final water content (%) |

|

Inorganic slat |

Harlsalz |

Barium stearate |

40 |

0.5 |

|

Zinc stearate |

40 |

0.5 |

||

|

Aluminum stearate |

45 |

2.0 |

||

|

Calcium stearate |

40 |

2.5 |

||

|

Magnesium stearate |

45 |

5.0 |

||

|

Carbonate |

Manganese carbonate |

20 |

1.0 |

|

|

Cerium carbonate |

31 |

17(include crystal water) |

||

|

Zinc carbonate |

80 |

0.5 |

||

|

Calcium carbonate |

30 |

0.2 |

||

|

Oxide |

Zirconia |

80 |

1.0 |

|

|

Iron oxide red |

60 |

1.0 |

||

|

Zinc oxide |

60 |

1.0 |

||

|

Chlorate |

Aluminum hydroxide |

55 |

1.0 |

|

|

Cuprous chloride |

45 |

1.0 |

||

|

Sulfate |

Sodium isocyanurate dioxide |

25 |

1.0 |

|

|

Calcium sulfate |

35 |

3.0 |

||

|

Sodium pyrosulfite |

20 |

0.2 |

||

|

Other |

Silica |

85 |

0.5 |

|

|

Lead sulfate |

|

|