Changzhou Fuyi Drying Equipment Co., Ltd.

Address: No. 212 Huaxing Road,Jintan Development Zone,Changzhou,Jiangsu,China

Tel: 0086-519-80181222

Fax: 0086-519-80181222

Mobile: 0086-18706143009

Skype:syhjtyz

E-mail: fy@fuyigz.com;

steven@fuyigranulation.com

Contact person: STEVEN

PRODUCT DESCRIPTION

PLG Series Continuous disc dryer is a high efficiency conducting and continuous drying equipment. Its unique structure and operating principle determine that it has advantages of high heat efficiency, low energy consumption, small occupied area, simple configuration, easy operation and control as well as good operating environment and etc. It can be widely used in drying process in the fields of chemical, pharmaceuticals, agricultural, foodstuff, feed, and other industries.

There are three major types: normal pressure type, closed type, and vacuum type; and four major models: 1200, 1500, 2200 and 3000; and three kind of material grades, A (carbon steel), B (use stainless steel for material contacted area), and C (use stainless steel for material contacted area, steam pipes, main shaft and supports, and linings for cylinder body and top cover).The drying area of the dryer is 4 to 180 m2. We have produced hundreds of models with auxiliary devices which are available to meet requirements of all customers.

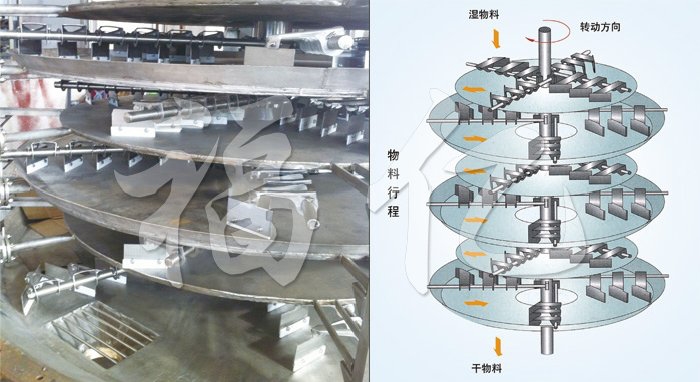

WORKING PRINCIPLE

The wet material is fed continuously to the first drying layer on the top of the dryer. It will be turned and stirred by rakes when the rake arm rotates and drop down to the outer edge of the large drying plate along the exponential helical line. The material will be moved from the small drying plate to its outer edge and drop down to the outer edge of the large drying plate underneath. Both small and large drying plates are arranged alternately so the materials can go through the dryer continuously. The heat medium can be saturated steam, hot water or thermal oil. The heat will be led into hollow drying plates from one end and come out from the other end. The dried materials will drop from the last layer of the drying plate to the bottom of the dryer and then moved by rakes to the discharge outlet. The material moisture will be removed from the exhaust outlet on the top cover. For the vacuum-type plate dryer, the moisture will be sucked out by the vacuum pump on the top cover. The dried materials will be discharged from the bottom layer. The drying capability can be improved if the dryer equipped with supplementary devices such as finned heater, condenser for solvent retrieval, bag dust remover, return and mix mechanism, draft fan, and etc.

FEATURES

(1)Easy to adjust and control, good applicability.

◎The drying efficiency can be improved by adjusting the thickness of material layer, rotary speed of main shaft, quantity of harrow arm, shape and size harrow plates.

◎Each drying layer can input hot medium or cool medium individually for heating or cooling. The temperature control is accurate and easy to adjust.

◎ The residence time of materials can be adjusted accurately.

◎Single material flowing direction to prevent material return and mixing. The drying process is uniform and the quality stable, no re-mixing is required.

(2)Easy to operate

◎Simple operation for turn on and turn off.

◎After material feeding is stopped, the remaining material inside of the machine can be easily discharged out by the harrows.

◎You can clean and observe inside from the large-scale viewing window.

(3)Low energy consumption

◎The material layer is thin and the rotary speed of main shaft is low so it required low power and electricity consumption.

◎The material is dried by conducting heat so it has high heating efficiency.

(4)Good operation environment

◎Normal pressure type:The speed of air flow inside of the machine is low and the humidity is high in upper end and low in bottom end so the dust can’t float to the top which keeps no dust in the exhausted air.

◎Closed type: The machine is equipped with solvent recovery device which can recover organic solvent easily from the wet air. The solvent recovery device has a simple structure and high recovery rate. For the flammable, explosive and poisonous materials, the nitrogen can be used as medium for closed circulation and keeps a safe working condition.

◎Vacuum type: The plate dryer is operating under vacuum condition and it is particularly suitable for drying heat sensitive materials.

(5)Easy installation

◎The dryer is delivered in a complete piece so it is quite easy to install and fix at site.

◎The disc plates are being arranged by layers and it will be installed vertically so it takes a small occupying area from the workshop.

Technical characteristics

(1) Drying plate

Design pressure: Generally 0.4MPa, up to 1.6MPa.

1.Maximum working pressure: generally less than 0.4MPa, up to 1.6MPa.

2.Heating medium: steam, hot water, heat conducting oil and drying plate. Use hot water when it is 100 degrees centigrade. When 100℃~150℃, heating with less than 0.4MPa saturated steam or superheated steam. When 150℃~320℃, Heating with a heat conducting oil. When >320℃,it is heated by electric, heat conducting oil and molten salt.

(2)Material delivery system

1. 1~10 rpm, electromagnetic or variable frequency stepless speed regulation.

2. Rake arm: each layer of drying tray has 2~8 arm arms attached to the main shaft.

3. Rake blade: hinged on the rake arm, can float up and down with the surface to keep in touch, there are many forms.

4. Roll: it can strengthen the heat transfer and drying process when the material is easy to agglomerate and need to be crushed.

(3) The shell has three types of atmospheric pressure, airtight and vacuum.

1. Atmospheric type: Cylinder or eight prism type with two structures: integral and opposite. The heating medium inlet and outlet main pipe can be in the shell or in the shell.

2. Closed type:A cylindrical shell that can withstand 5Kpa internal pressure, the heating medium inlet and outlet main pipe can be in the shell or in the shell.

3. Vacuum type: cylindrical shell, the design pressure is 0.1Mpa, the heating medium inlet and outlet main pipe is in the shell.

(4)Air heater

Generally used in the case of large evaporation, in order to enhance drying efficiency.

Adaptive material

Organic chemical products, inorganic chemicals, pharmaceuticals, foodstuffs, feedstuffs, fertilizers

|

Specifications |

External diameter mm |

Height mm |

Drying area m2 |

Power Kw |

|

1200/4 |

Φ1850 |

2718 |

3.3 |

1 |

|

1200/6 |

3138 |

4.9 |

||

|

1200/8 |

3558 |

6.6 |

1.5 |

|

|

1200/10 |

3978 |

8.2 |

||

|

1200/12 |

4398 |

9.9 |

2.2 |

|

|

1500/6 |

Φ2100 |

3022 |

8.0 |

|

|

1500/8 |

3442 |

10.7 |

||

|

1500/10 |

3862 |

13.4 |

||

|

1500/12 |

4282 |

16.1 |

3.0 |

|

|

1500/14 |

4702 |

18.8 |

||

|

1500/16 |

5122 |

21.5 |

||

|

2200/6 |

Φ2900 |

3319 |

18.5 |

|

|

2200/8 |

3739 |

24.6 |

||

|

2200/10 |

4159 |

30.8 |

4.0 |

|

|

2200/12 |

4579 |

36.9 |

||

|

2200/14 |

4999 |

43.1 |

5.5 |

|

|

2200/16 |

5419 |

19.3 |

||

|

2200/18 |

5839 |

55.4 |

7.5 |

|

|

2200/20 |

6259 |

61.6 |

||

|

2200/22 |

6679 |

67.7 |

11 |

|

|

2200/24 |

7099 |

73.9 |

||

|

2200/26 |

7519 |

80.0 |

|

Specifications |

External diameter mm |

Height mm |

Drying area m2 |

Power Kw |

|

2500/6 |

Φ3150 |

3319 |

26.3 |

4 |

|

2500/8 |

3739 |

35 |

||

|

2500/10 |

4159 |

43.8 |

5.5 |

|

|

2500/12 |

4579 |

52.5 |

||

|

2500/14 |

4999 |

61.3 |

7.5 |

|

|

2500/16 |

5419 |

70 |

||

|

2500/18 |

5839 |

78.8 |

11 |

|

|

2500/20 |

6259 |

87.5 |

||

|

2500/22 |

6679 |

96.3 |

||

|

2500/24 |

7099 |

105 |

13 |

|

|

2500/26 |

7519 |

113.8 |

||

|

3000/8 |

Φ3800 |

4050 |

48 |

11 |

|

3000/10 |

4650 |

60 |

||

|

3000/12 |

5250 |

72 |

||

|

3000/14 |

5850 |

84 |

||

|

3000/16 |

6450 |

96 |

||

|

3000/18 |

7050 |

108 |

13 |

|

|

3000/20 |

7650 |

120 |

||

|

3000/22 |

8250 |

132 |

||

|

3000/24 |

8850 |

144 |

||

|

3000/26 |

9450 |

156 |

15 |

|

|

3000/28 |

10050 |

168 |