Changzhou Fuyi Drying Equipment Co., Ltd.

Address: No. 212 Huaxing Road,Jintan Development Zone,Changzhou,Jiangsu,China

Tel: 0086-519-80181222

Fax: 0086-519-80181222

Mobile: 0086-18706143009

Skype:syhjtyz

E-mail: fy@fuyigz.com;

steven@fuyigranulation.com

Contact person: STEVEN

Product introduction

The machine adopts full sealing for it . All parts are made of stainless steel. It is equipped with three grades of filter. The filtered air is one hundred thousand grades. The cooling device of wall is installed at the cylinder body. It makes the wall temperature less than 80℃.Air sweeping device is installed inside the drying tower. The product will not be burnt or deteriorated even stays on the way. The collection rate of powder is raised greatly. Moreover will not cause medicine mixed or wall stick.

Working principle

Spray dryer machine for Chinese medicine medicinal is an application of centrifugal spray drying technology in drying of special materials, also use high-speed centrifugal atomizer to make the material dispersed into fog,fully contact with drying hot air, complete drying at once, forming powder finished products.

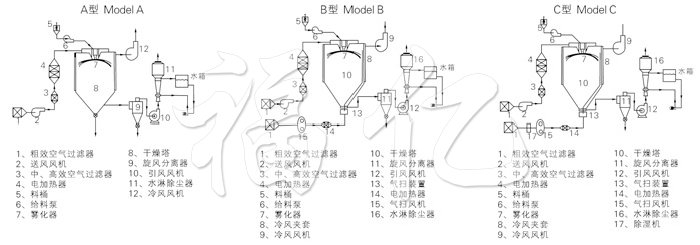

Schematic drawing

(2).Adopted wall cooling device,the temperature of inner wall will be on more than 80℃.Even if raw material is stayed on the wall,it will not be burnt

(3).Its whole volume is 3.5 times of standard LPG high-speed atomizing dryer.

(4).Adopted quick washing device,it is can meet the requirements of production for varieties if products.

(5).Adopted wet-dedusting,there is no powder dust out.It is in conformity with the requirements of GMP.

(6).Adopted air sweeping device ,the clean effect is satisified.

(7).Equipped with two sets of atomizer and adopted frequency inverter control.

(8).Adopted PLC control and display,and adapted frequency control.

(9).Equipped with washing device on request.

Technical specifications

|

Model |

ZLPG-15 |

ZLPG-20 |

ZLPG-25 |

ZLPG-32 |

ZLPG-38 |

ZLPG-40 |

ZLPG-47 |

ZLPG-52 |

ZLPG-58 |

|

|

Moisture evaporation |

5 |

10 |

25 |

50 |

80 |

100 |

150 |

200 |

300 |

|

|

Material handling capacity |

6-7 |

12-14 |

25-34 |

50-68 |

80-108 |

100-135 |

150-203 |

200-270 |

300-406 |

|

|

Finished product output |

1-2 |

2-4 |

4.8-7.2 |

9.2-14 |

14.8-22.4 |

18.4-28 |

28-42 |

36.8-56.4 |

55-85 |

|

|

Solid content of wet material |

18-25 |

|||||||||

|

Water content of finished product |

3-5 |

|||||||||

|

Electric power |

36 |

45 |

63 |

99 |

132 |

153 |

204 |

246 |

330 |

|

|

Heating source |

Steam + electricity |

|||||||||

|

Product collection methods and collection efficiency |

A point or two: a collection of more than 95% |

|||||||||

|

Automatic instrument |

Temperature and pressure automatic control, adjustment, interlock alarm |

|||||||||

|

Inlet air temperature |

150-200 |

|||||||||

|

Outlet temperature |

80-100 |

|||||||||

|

Overall dimension (mm) |

Length |

5000 |

5500 |

7000 |

8000 |

9800 |

11000 |

12200 |

14100 |

15000 |

|

Width |

3000 |

3500 |

4000 |

5000 |

5700 |

6200 |

7000 |

7800 |

9000 |

|

|

Height |

4500 |

4600 |

5200 |

6500 |

7600 |

8100 |

9000 |

9850 |

11100 |

|

Note:★The actual size can be determined according to the actual situation of customers. The above size is for reference only.

★The amount of evaporation above is the maximum amount of evaporation.